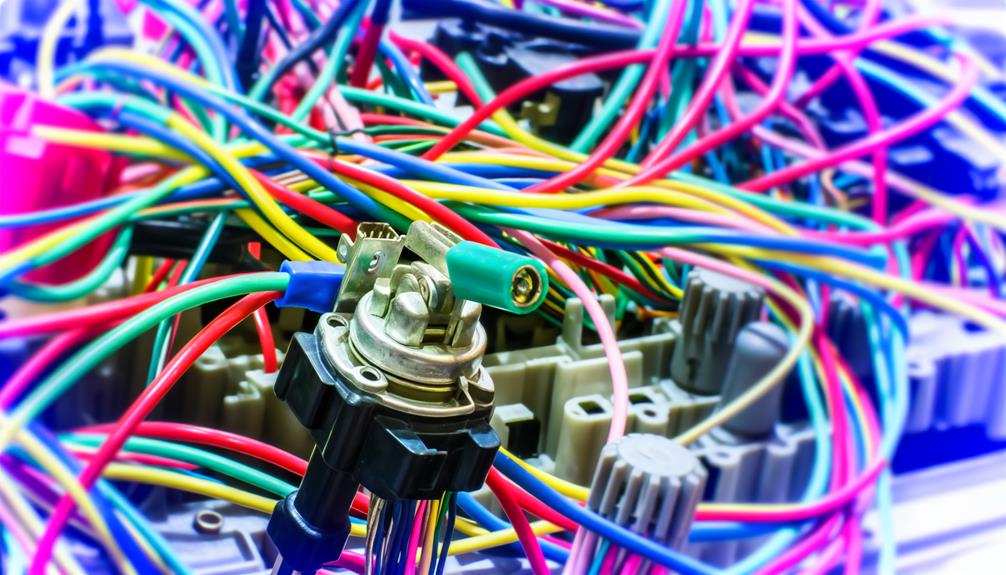

In the intricate maze of automotive electrical systems, the color coding of Chevy ignition switch wires stands out as a beacon for professionals navigating repairs and diagnostics.

This systematic approach, employing specific hues like red for power supply and pink for ignition feeds, serves not only to streamline the troubleshooting process but also significantly mitigates the risk of electrical mishaps.

However, the implications of these color codes extend beyond mere convenience and safety. The question then arises: how does understanding these color distinctions impact the efficiency of diagnosing electrical issues in Chevy vehicles? Let us explore the depth of this seemingly simple yet profoundly critical aspect of automotive maintenance.

Contents

Understanding Color Codes

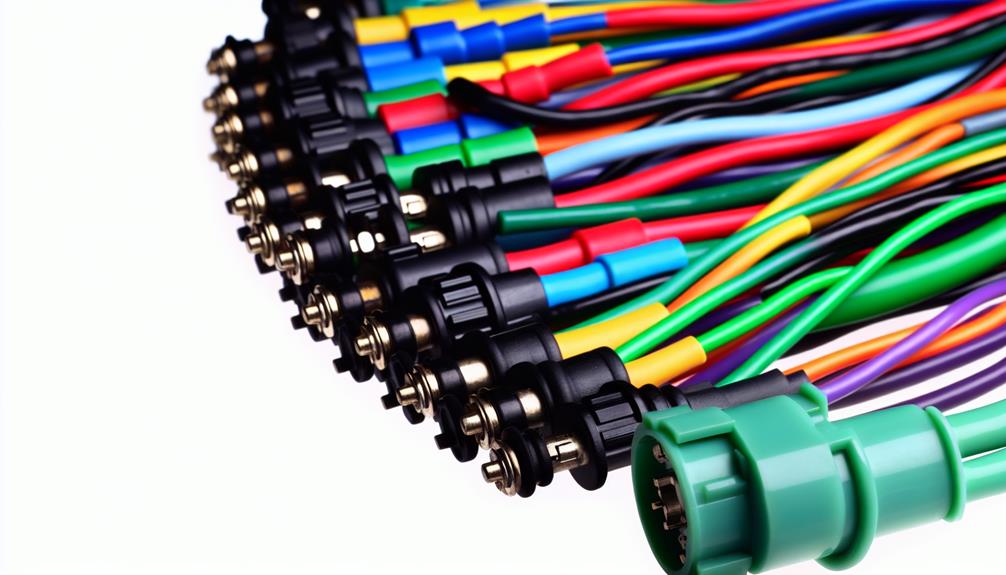

Deciphering the color codes in Chevy ignition switch wiring is crucial for accurately identifying and connecting the various components and circuits within the vehicle’s electrical system. The ignition system utilizes a spectrum of colors such as red for constant power, pink for ignition-powered circuits, brown for accessory power, and purple for starter circuit connections.

These color codes serve as an essential guide for technicians and enthusiasts alike, ensuring correct connections that are vital for the vehicle’s operation. Moreover, specialized colors like light blue and dark blue indicate turn signal circuits, whereas yellow and green often pertain to brake lights and exterior lamps.

Understanding these color codes is fundamental in maintaining the integrity of the ignition system, preventing potential electrical issues, and facilitating efficient troubleshooting and repairs.

Importance of Wiring Systems

A well-designed wiring system is pivotal in ensuring the reliability and safety of automotive operations, particularly in the intricate electrical networks of vehicles like Chevrolets. Utilizing color codes is a critical aspect of these systems, significantly streamlining the processes of maintenance, troubleshooting, and repair.

By employing a standardized color code, Chevy wiring systems facilitate a uniform understanding among technicians, reducing the potential for errors. This methodical approach to wiring not only enhances the efficiency of identifying and addressing electrical issues but also plays a crucial role in mitigating risks associated with electrical hazards.

Consequently, the application of color codes in Chevy’s wiring schema is indispensable, ensuring that each wire’s function is immediately apparent, thereby improving overall vehicle safety and operational integrity.

Benefits of Color Coding

Given the critical role of wiring systems in vehicle safety and functionality, the implementation of color coding offers significant advantages in automotive electrical operations. By facilitating the identification of wire functions across devices, color coding directly contributes to both safety and efficiency.

It significantly reduces downtime and optimizes repair efficiency by streamlining the troubleshooting processes. The use of distinct colors to indicate power flow direction enables technicians to swiftly identify wire functions, thereby simplifying complex electrical diagnostics.

Furthermore, color coding minimizes the risk of electrical shock, fires, and burns, substantially enhancing safety during wiring and repairs. Chevy’s adoption of specific color schemes for wiring ensures that these benefits are readily accessible, supporting safe and efficient maintenance and repair activities within various automotive systems.

Decoding Chevy Wire Colors

Understanding the color coding of Chevy wiring is essential for accurate identification and troubleshooting of electrical components within the vehicle. The Chevy color code system facilitates the efficient diagnosis and repair of electrical circuits.

For instance, the ignition switch wiring harness employs a 10 RED wire for both the alternator battery feed and ignition switch battery, integral to the vehicle’s power distribution network. Similarly, turn signal functionality relies on 16 LIGHT BLUE and 16 DARK BLUE wires for left and right front signals, respectively.

This meticulous color distinction extends to exterior lamp wiring, with 14 GREEN indicating battery feed from the headlight switch fuse and 14 BLUE denoting headlight switch output. Such precision in wire color coding underscores the importance of understanding Chevy’s systematic approach to vehicle electrical design.

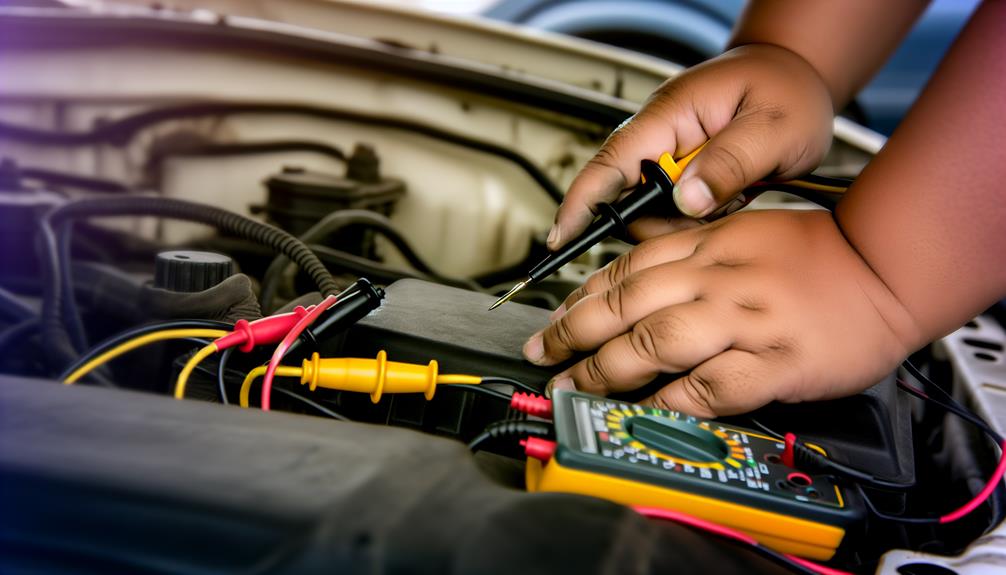

Troubleshooting Electrical Issues

Efficiently diagnosing electrical issues in Chevy vehicles significantly depends on accurate identification of wire functions through their color codes. Understanding the color-coded wiring is essential for ensuring the correct connections for Chevy Ignition Switch components. The specific wire gauge and insulation, dictated by color, are crucial for proper function and safety. Moreover, pinout information corresponding to each wire in the ignition system is indispensable for diagnosing and effectively resolving problems. Testing the continuity of wires, guided by their color-coding, facilitates a swift resolution of electrical faults, streamlining the process of wiring your car.

| Wire Color | Function |

|---|---|

| Red | Power Supply to Switch |

| Yellow | Starter Circuit |

| Brown | Accessory Position |

Conclusion

In conclusion, the use of standardized color codes in Chevy’s ignition switch wiring significantly enhances the efficiency of diagnosing and repairing electrical issues within the automotive system.

This systematization not only facilitates the rapid identification and resolution of wiring concerns but also substantially mitigates the risk of electrical hazards.

It underscores the pivotal role of precise, color-coded wiring in ensuring the safety and reliability of automotive electrical systems, thereby underscoring the critical nature of adherence to these established color conventions in automotive maintenance and repair practices.